"Thanks to Zapsi, we have identified capacity reserves and have been able to automate the information transfer process."

What does Kovo-plasma do:

- Engineering production

- Sheet metal processing

- Laser cutting

- CNC bending

Benefits of MES System Zapsi

- A comprehensive view of the individual sections in production

- Ability to monitor and evaluate the utilization of individual workplaces and specific machines

- More detailed transfer of information between systems

- More efficient work planning using the planner in our information system

Which units of the MES System Zapsi are used by the company:

Hardware:

- Zapsi Unit for collecting data from production machines

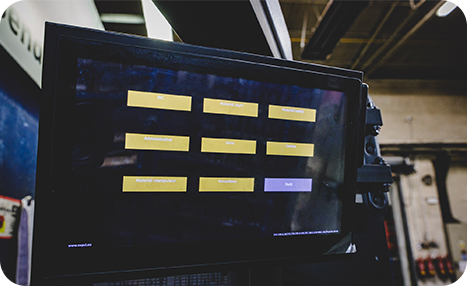

- Zapsi Touch to enter user data

- LCD display for visualisation on the production workshops

Software:

- The MES System Zapsi used to work with data obtained from machines, from users, from the company's information system

- Running user logic on Zapsi Touch terminals, created according to customer requirements

- Established communication between the MES System Zapsi and the company's information system - K2

Special Services:

- HW and SW installation at the customer's location

How was the implementation of the project:

We divided the implementation into two parts:

1. Hardware installation:

It was necessary to tighten the network and to install a diverting terminal to each workplace in the production. This stage was carried out very quickly and without any problems.

2. Program modifications:

The second stage was more complicated because we decided to connect the MES System Zapsi with our information system. Because zapsi collects data on how long a particular machine takes to process a production order, it was important for us to transmit this information.