Successful Project Implementation

THERMOPLASTIK s.r.o.

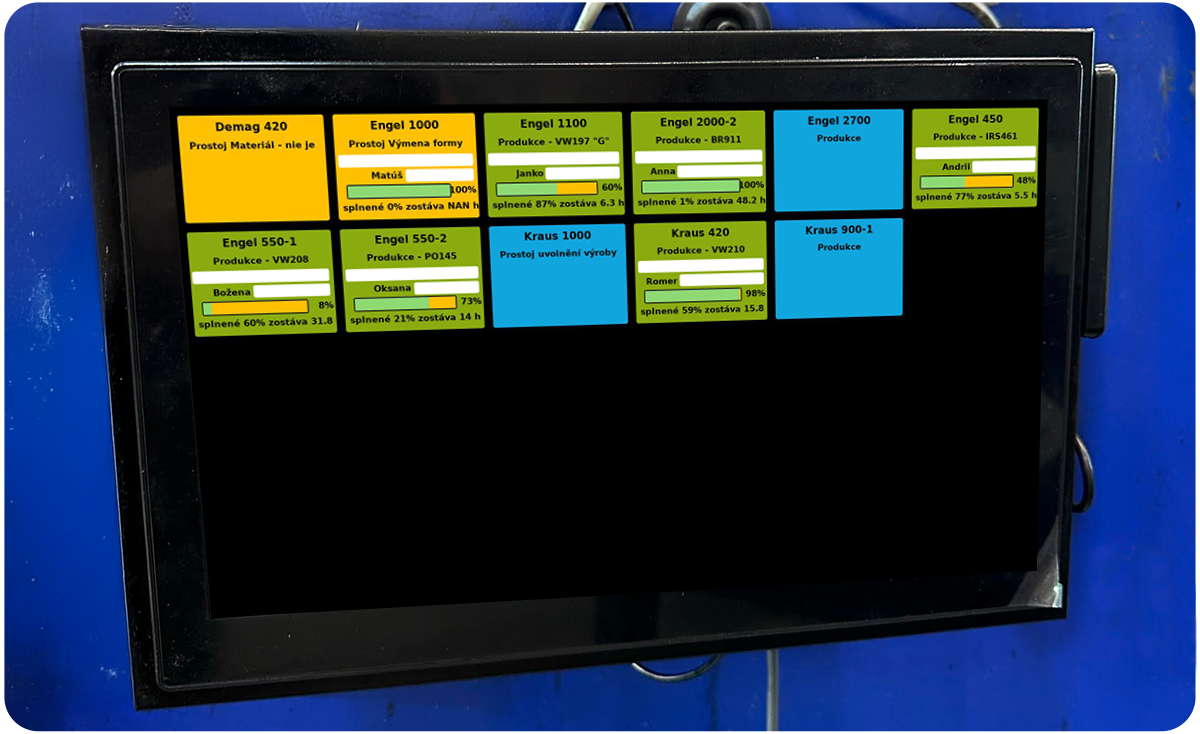

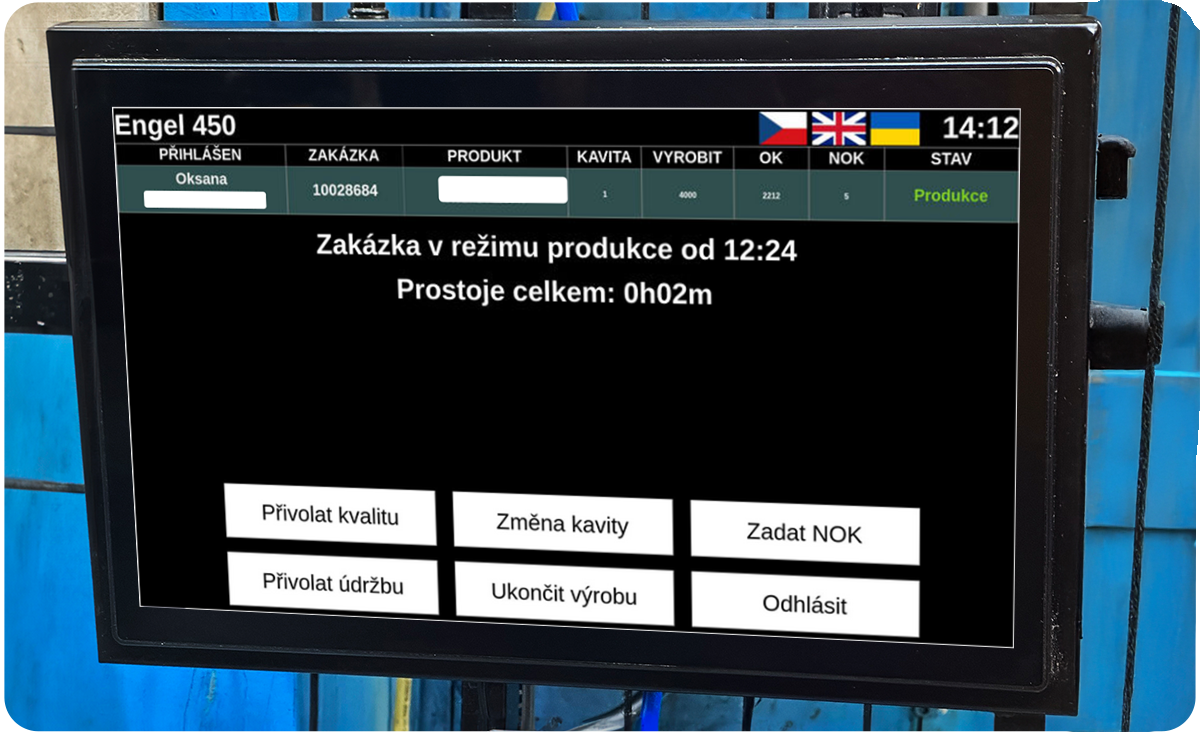

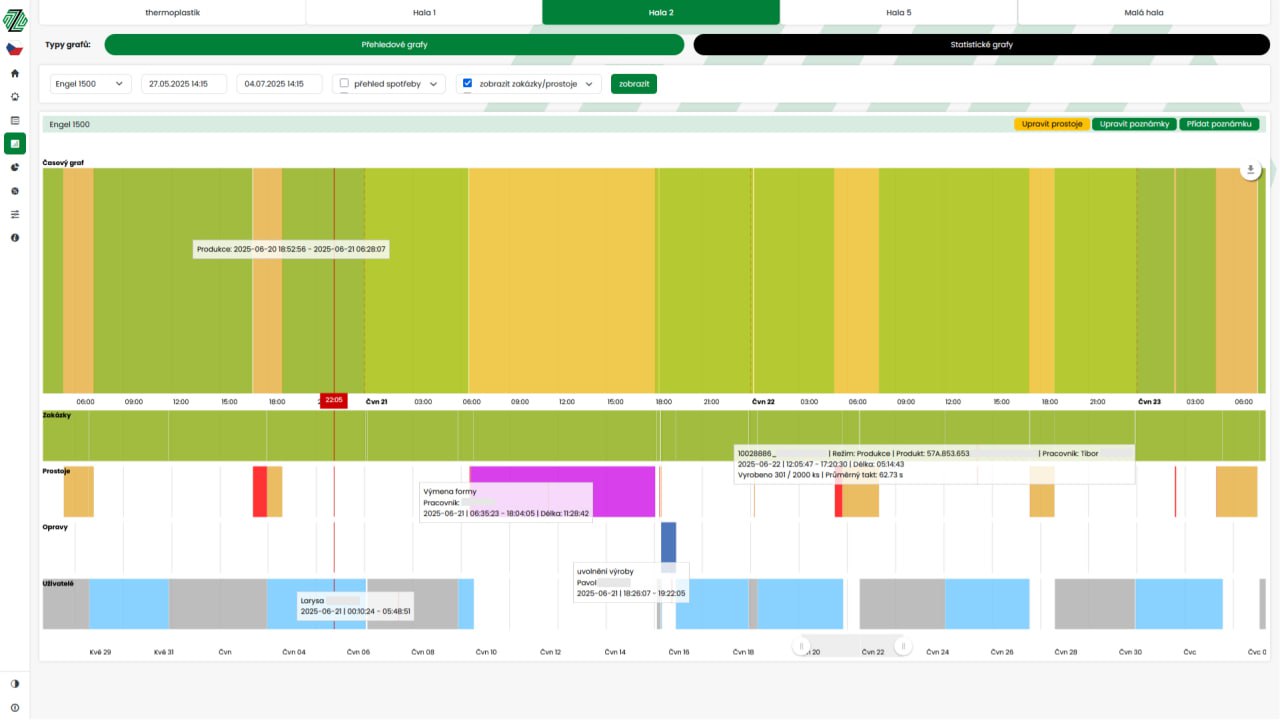

The main reason for acquiring the MES System Zapsi was to make effective use of machines and monitor their utilization. The MES System Zapsi enables us to track machine utilization and identify the causes of downtime — whether due to organizational issues or inappropriate operator behavior. Another key aspect was monitoring energy consumption. Thanks to Zapsi, we can integrate various machine signals, giving us deeper insight into consumption and technological parameters — supporting better understanding and efficient production management.

Simple and quick data acquisition in the following areas:

„A major advantage of the MES System Zapsi is that the unit, which measures electricity consumption and collects only two inputs plus operator inputs, can still provide a wealth of instantly available data for analysis and reporting — which is crucial in today’s volatile market.“

The workplace operation time chart clearly shows the timeline of workplace states — production, downtime, and off. It also includes additional information about loaded jobs, recorded downtimes (both from the terminal and the machine), ongoing repairs, and logged-in users.

The implementation of the MES System Zapsi was very smooth. THERMOPLASTIK had well-established processes, allowing the MES System Zapsi to be integrated without disrupting existing workflows — simply collecting data. This allowed for immediate live operation.

THERMOPLASTIK appreciated our experience with molding operations:

„We quickly found common ground and understanding of processes without unnecessary explanations.“

During implementation, there were naturally some challenges — for example, operator inputs needed adjustment due to error rates. There were minor cloud-related response issues, which Zapsi s.r.o. quickly resolved by modifying libraries and software.