Successful Project Implementation

SITEM SLOVAKIA s.r.o.

Collecting production data in real-time, available 24/7.

Initiating production digitalization to improve processes and increase efficiency.

“As they say, paper can take a lot, but the online system eliminated inaccuracies from manual data entry.”

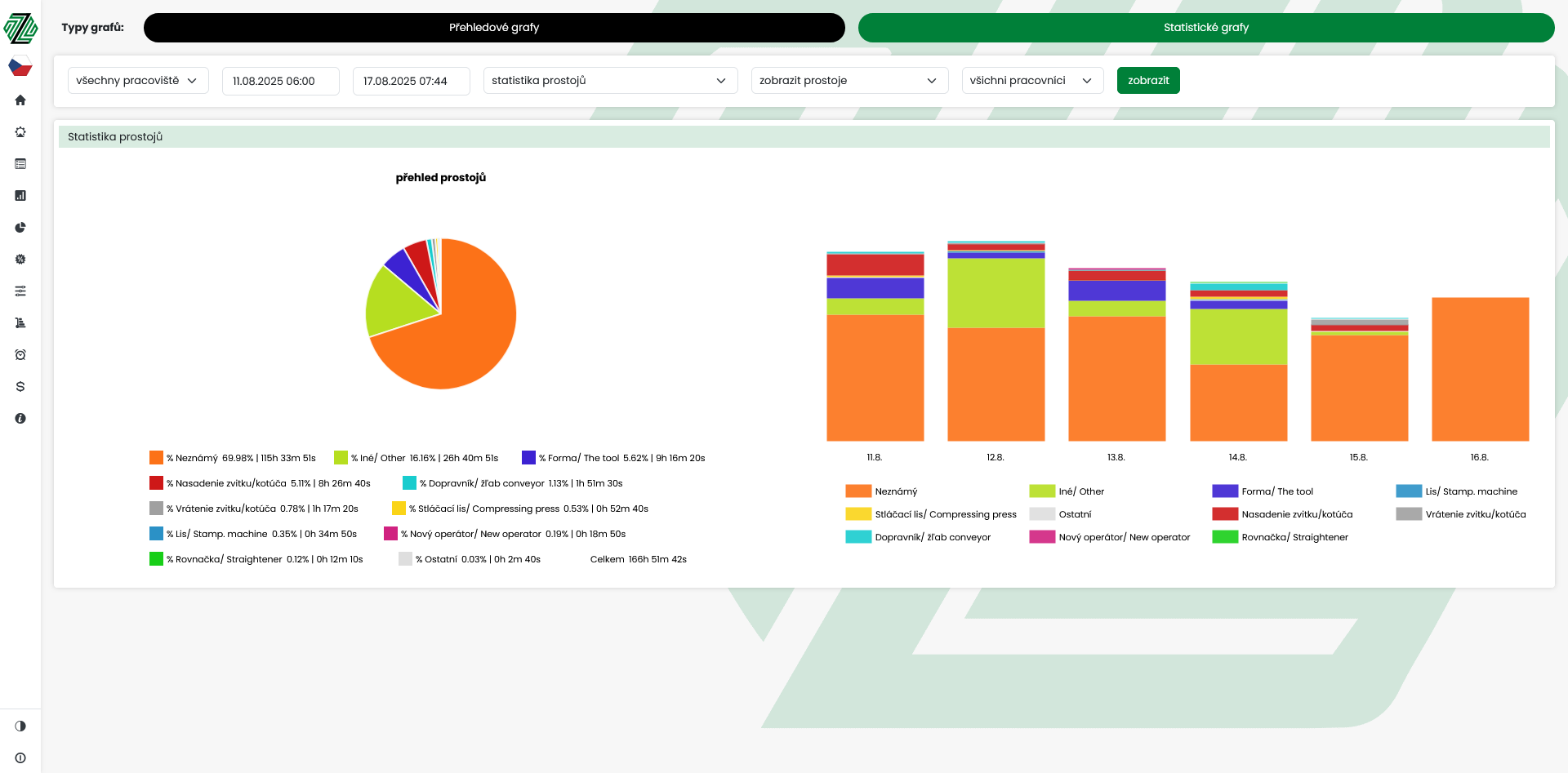

In this case, it is one of the key parts of the system that we use regularly – it provides a comprehensive overview of individual production workplaces. Within seconds, we obtain clear information about current events. If more detailed data is required, it is possible to use links to other parts of the system's user interface – Zapsi Web.

Information about downtime is also important to us. Thanks to the Zapsi system, we can easily eliminate or optimize unplanned—and therefore unwelcome—time losses.

The company decided to implement the Zapsi MES System including software and hardware adjustments:

Everything went smoothly and continues to operate correctly – from unit specification, offer preparation, fast delivery, to communication and specific software and hardware adjustments.

During implementation, there was only a misunderstanding of the reporting function – when the machine is idle vs. switched off (not clear from the original manual), but Zapsi resolved it quickly and efficiently.

“Overall, we appreciate the quick support and the customer portal.”

In the future (already in progress), the goal is full integration of the ERP system with the Zapsi MES System: